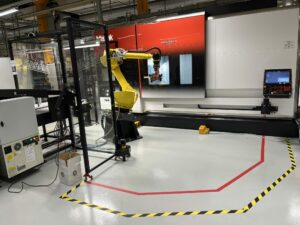

In Tierp our new Mazak Integrex multi-tasking-machine is in full operation.

The first job we implemented gave big process improvements:

Done-In-One-Machining – earlier two operations in two machines. Improved quality and lead time.

- Light-out-production – improves our capacity greatly, free up time for our operators/technicians.

- Environmentally friendly – with the new process, we were able to run the job with a smaller blank, saving 15% material. Less Co2 footprint per part.

MF Group company Ströms Mekaniska in Degerfors have just installed their very same Mazak Integrex. Through these investments, MG Group has a strong capacity for turned/milled parts.